随着AR技术的不断发展,镁合金作为一种轻量、高强度的材料,正逐渐成为AR眼镜制造中备受关注的材料之一。其优越的物理性能使得AR眼镜在保持轻盈舒适的同时,能够承受日常使用中的各种挑战。镁合金的高强度和耐腐蚀性质不仅增加了AR眼镜的耐久性,还为设计师提供了更大的创造空间,使得眼镜结构更为精致、流线型,为用户提供更为沉浸和舒适的增强现实体验。

歌尔首个基于第一代骁龙AR2的量产化轻量级AR智能眼镜参考设计使用碳纤维和镁锂合金作为眼镜外壳材料,降低重量的同时提升整体散热性能。

星纪魅族 AR 眼镜 MYVU Discovery 重量仅 71g,采用航空级镁铝合金,覆盖超 50% 镜身。

XREAL Air 2系列引入镁合金横梁、外壳超轻塑胶粒子等多项新材料,将产品非必须部位大幅减重。

本次小编将为大家介绍一种AR眼镜镁合金骨架加工工艺——半固态注射成型。

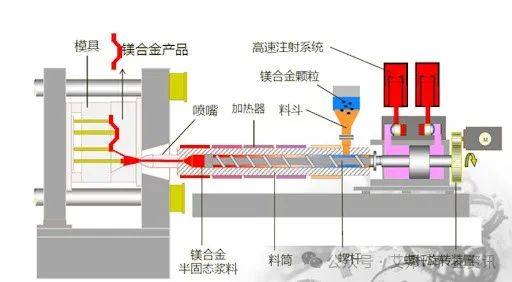

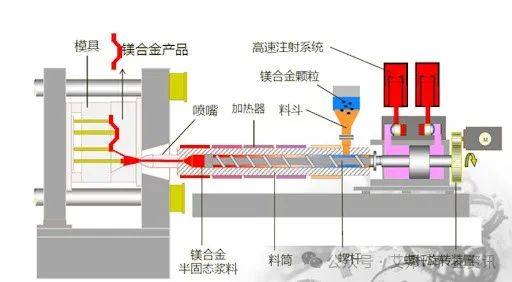

金属在凝固过程中,进行强烈搅拌或通过控制凝固条件,抑制树枝晶的生成或破碎所生成的树枝晶,形成具有等轴、均匀、细小的球状初生相均匀分布于液相中的悬浮半固态浆料。这种浆料在外力的作用下具有较好的流动性,可以利用多种工艺进行加工成型,称之为半固态成型。

米粒大小的镁合金原料在重力、负压下由料斗进入料管,经过螺杆旋转和料管外加热器提供热量,被剪切和加热,形成部分熔融状态的含有球形固相的半固态浆料,浆料流动性良好,在此状态将浆料高速压射入模具成型。

活动推荐:【邀请函】:第五届AR/VR/MR产业论坛(9月 深圳)

|

serial number

|

|

|

|

AR/VR/MR's Computational Paradigm Transformation from Micro to Macro

|

|

|

Current Status and Future Trends of the AR/VR Industry Market

|

|

|

Design and Material Selection Differences Between Consumer and Industrial AR/VR Products

|

|

|

Design of VR Pancake Optical Module

|

|

|

Application of Nanoscale Imprint Technology on AR Gratings

|

|

|

The Development of AR Waveguide Technology

|

|

|

Application of Superlenses in AR/VR

|

|

|

The Development of Freeform Surface Technology in the AR/VR Field

|

|

|

The Development Progress of Micro LED/OLED in AR/VR

|

|

|

Challenges in the Development of Full-Color Micro LED for AR

|

|

|

VST: Cornerstone Technology for MR, Propelling the Era of Spatial Computing

|

|

|

The Application of Cameras in AR/VR Headsets

|

|

|

The Development of Gesture Recognition and Eye Tracking Technologies in AR/VR

|

|

|

Development and Application of Lightweight Materials in AR/VR

|

|

|

Assembly Equipment for AR/VR Complete Systems and Optical Modules (AA Assembly)

|

|

|

Application of Optical Materials in AR/VR

|

|

|

Coating and Curved Bonding Solutions for AR/VR Lens

|

|

|

The Application of Sensing Devices in AR/VR

|

|

|

The Application of Electrochromic Materials in AR/VR

|

|

|

Materials and Processing Solutions for Structural Components in AR/VR

|

|

|

Spatial Audio Technology Solutions for AR/VR

|

|

|

Energy Consumption and Heat Dissipation Solutions for AR/VR

|

Feel free to reach out to the forum registration coordinator for more innovative topics and ideas: Ai Lulu, 15817337805 (also on WeChat)

Registration Method 1: Add on WeChat and Submit Business Card for Registration

Contact Ai Lulu: 15817337805 (same for WeChat)

Registration Method 2: Online Registration

https://www.aibang360.com/m/100192

Alternatively, scan the QR code to access the registration page and enter your information

阅读原文,在线报名

The original article was first published on the WeChat official account (Aibang VR Industry News):AR眼镜镁合金骨架加工工艺——半固态注射成型